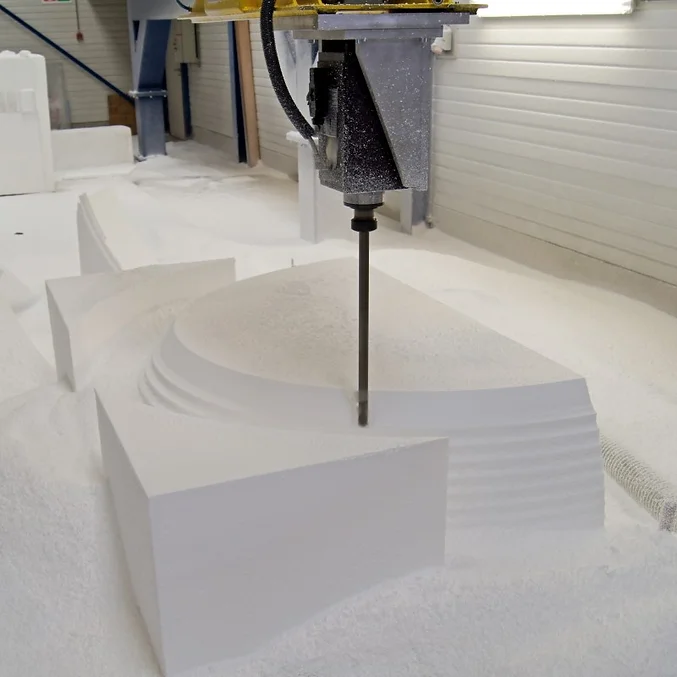

Basic shape for polyester mould

A basic model is milled to size in expanded polystyrene (EPS) or polyurethane (PU). On this model, you can apply a (master) mould in polyester or epoxy resin. The polyester or epoxy resin mould can then in turn be used to produce the final pieces.

Polyester may be used directly on PU but not directly on EPS! Moulds in EPS must first be provided with a fully waterproof coating before applying polyester. Epoxy resin may be applied directly to EPS and PU.

Police Station

Basic shape for atlanteans

The 3.6m-high polyester ‘facade agents’ were produced with a milled base form.

This project was awarded the Boston Society of Architects’ prestigious Honor Award for Design Excellence.

Group T

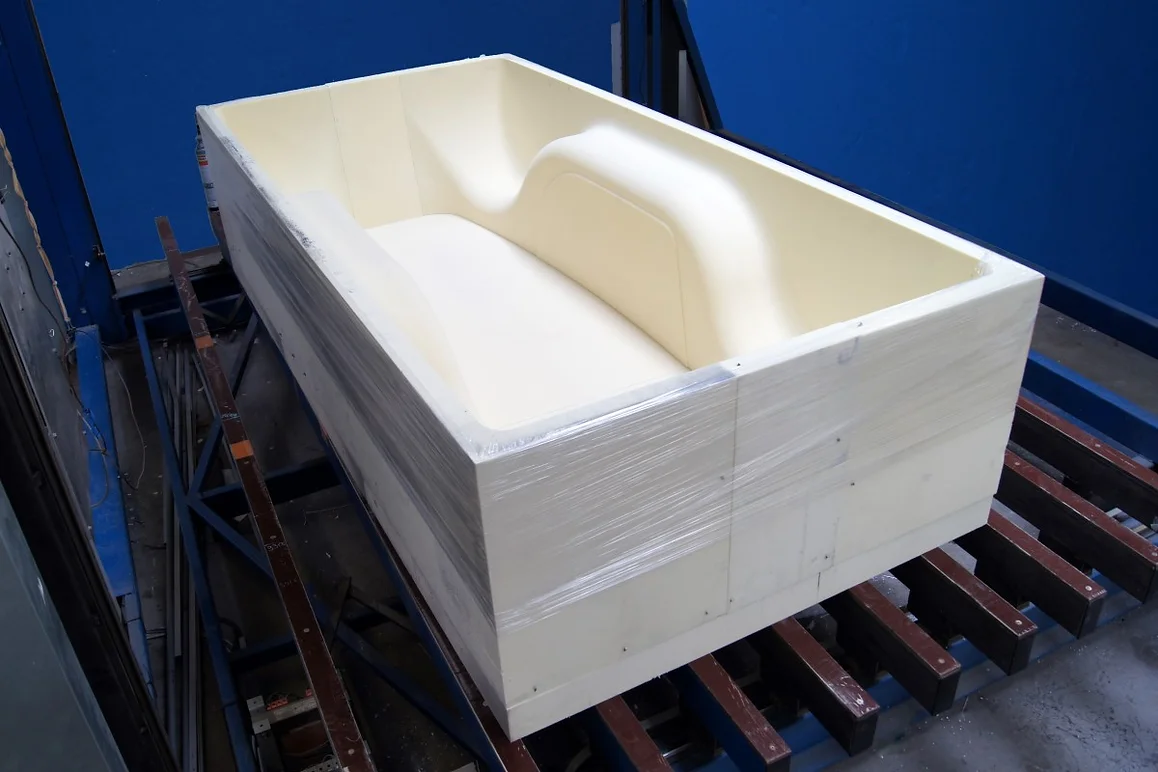

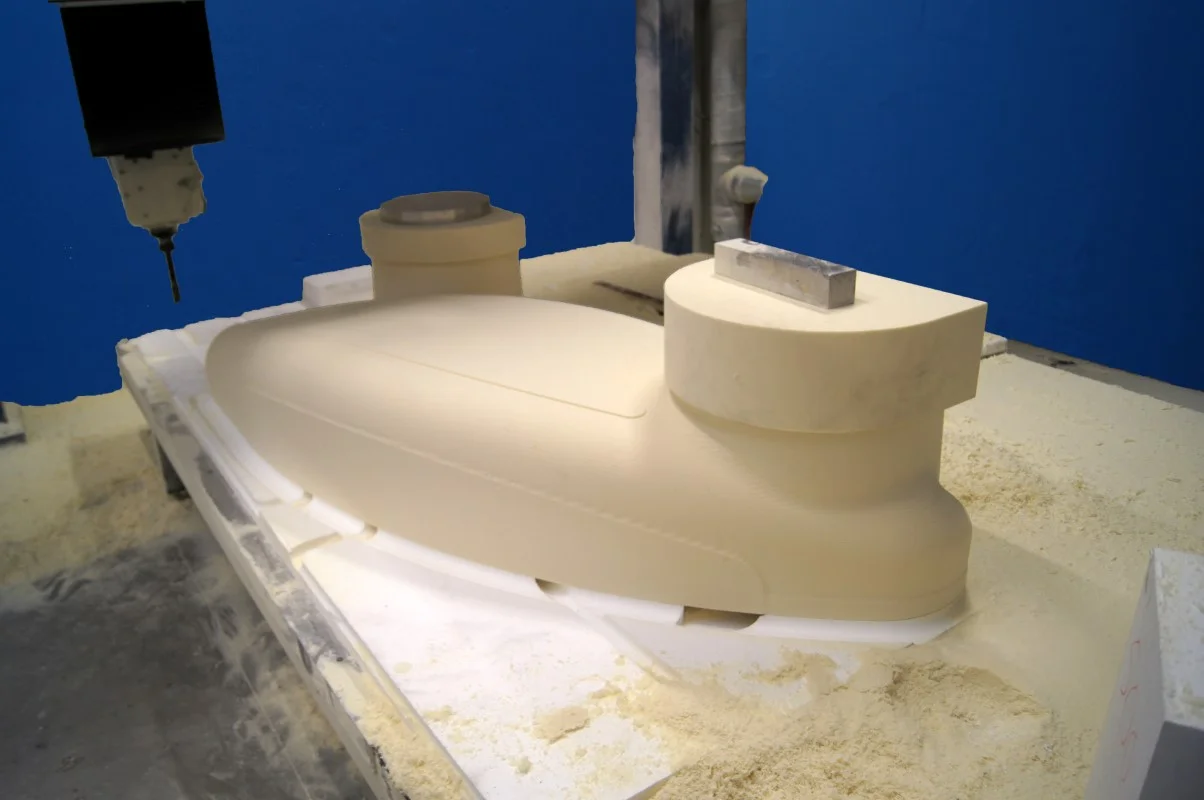

Basic shape for monocoque chassis for car ‘June’

Group T students drew a flange on the supplied 3D drawing. This is the extra straight part next to the basic shape. This is how they poured the polyester master mould with a tight and nicely shaped concatenation.

Talking Candy Machine

Basic design milled in PU40 (yellow) and PU80 (green)

Glorifier display Côte d’or

Basic design VW van in PU40

Glorifier display Milka

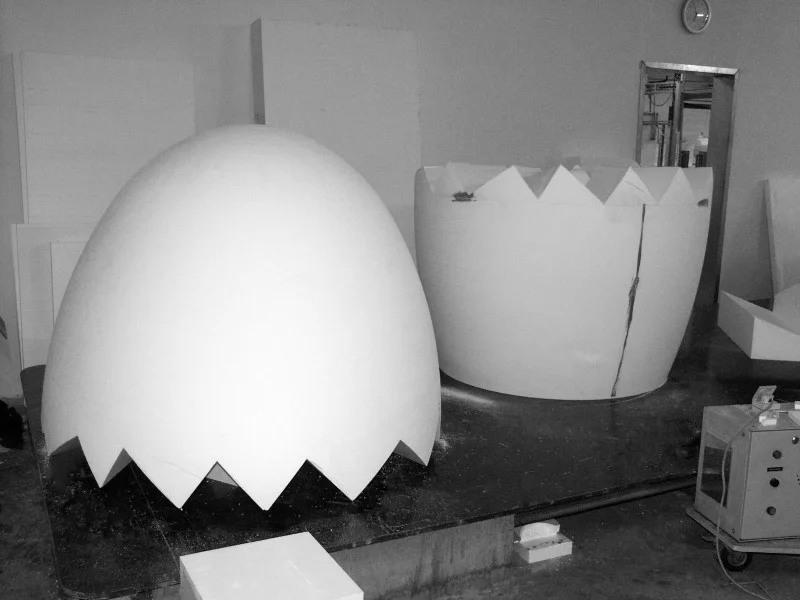

Basic design in EPS for presentation egg

Thomas More

Basic shapes for the trolley for the Eco Drive Marathon. Thomas More students designed this car for the Eco Drive Marathon. In this competition, the aim is to build the most economical city car possible.

Negative base form in PU40 for one-time lamination of the car’s chassis.

Thomas More

Positive base form for the car in PU40

Mobile bar Limoncello

Basic design in EPS

Waterslide

Basic design in PU

Vase

3D milled basic design in EPS

Artwork

3D scanned and basic design in PU