PU/PIR

PU (PUR) or polyurethane foam and PIR or polyisocyanurate are thermoharders (cannot be reused because the structure is chemically adjusted, which means that it does not melt to become a raw material but it carbonises). These chemical adjustments means that PU and PIR are available in various hardnesses and densities (40 kg/m³, 60 kg/m³, 80 kg/m³ and 120 kg/m³). A choice is made in relation to this based on the application.

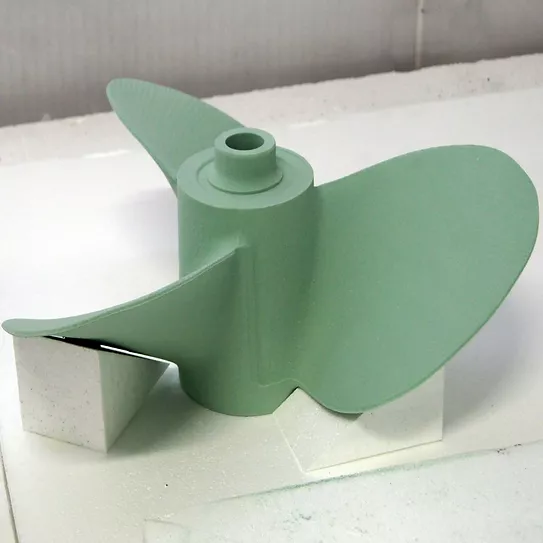

PU and PIR can be easily processed via contour sawing and routing since this foam is characterised because of its rigidity. PU and PIR also have a homogeneous structure which means that you obtain a uniform surface after routing. In addition, PU and PIR (in contrast to EPS) are compatible with polyester and it is therefore extremely suitable to finish with polyester or to coat it (both on a solvent-base such as epoxy resin and fibre-reinforced synthetic resin).

PU’s characteristics are that it retains its form at a temperature between -180 °C and 100 °C. PIR is an adjusted PU variant with the same characteristic and it is also not flammable and very suitable for the insulation in insulation sleeves. PIR can withstand temperatures from -200 °C to 120 °C and PIR-HT can even withstand them up to 200 °C. Without a finishing coat, PU and PIR discolour in sunlight to a brown colour. PU and PIR absorb little moisture and it is therefore waterproof. In addition, it has a strong shape stability and it will not easily crack.

Find your tailor-made solution

Contact us and we will send you a custom made offer within 7 days.