Vacuum forming

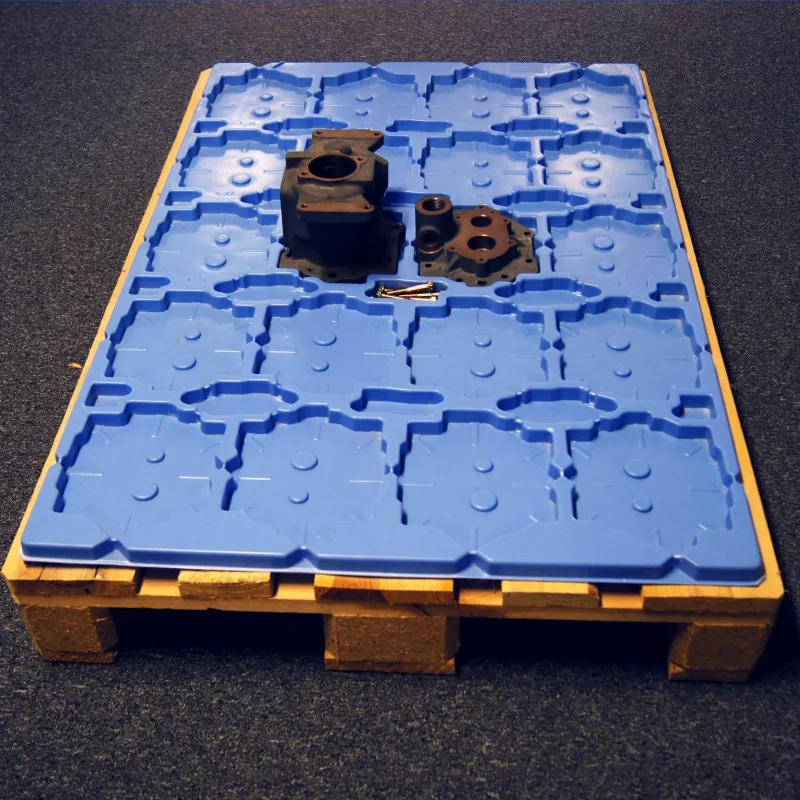

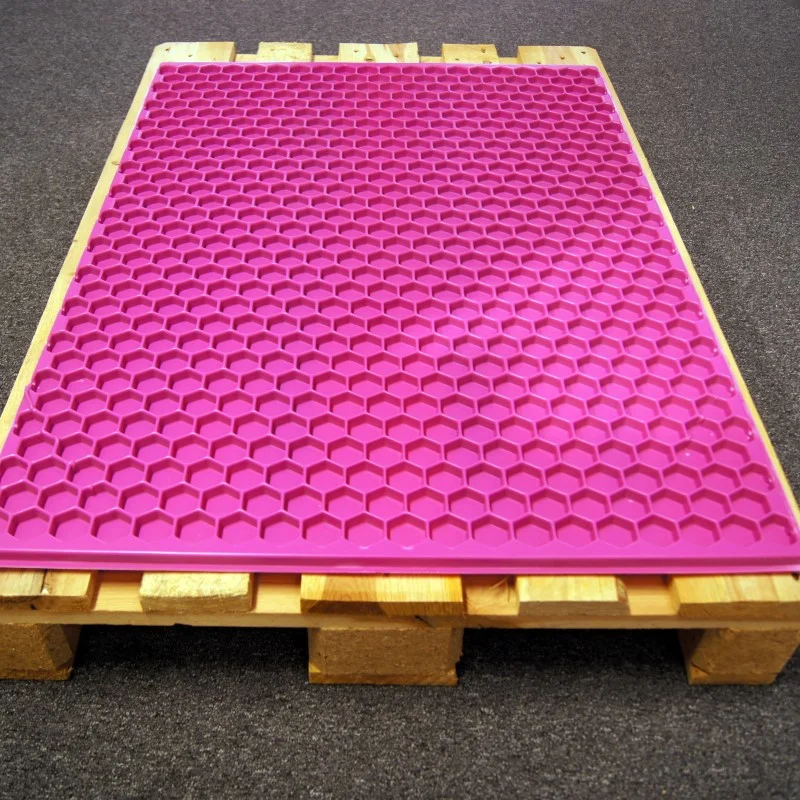

In relation to vacuum forming, which is also referred to as thermoforming, we start of from a granulate (PP or PS) that we extrude to obtain an elastic film with a thickness of at most 6 mm. The film is stretched over a mould die after which it is all vacuum suctioned during a continuous process. The film will retain the shape of the die due to cooling down and afterwards the end product is cut out using a punching machine and a guillotine. We can handle various dimensions up to a euro pallet format.

The aluminium mould dies are routed in our own workshop. Specific colours or even an additive (for example, talc) are part of the options.