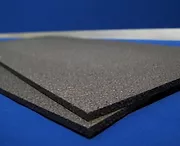

EPS styrofoam

EPS (expanded polystyrene, styrofoam)

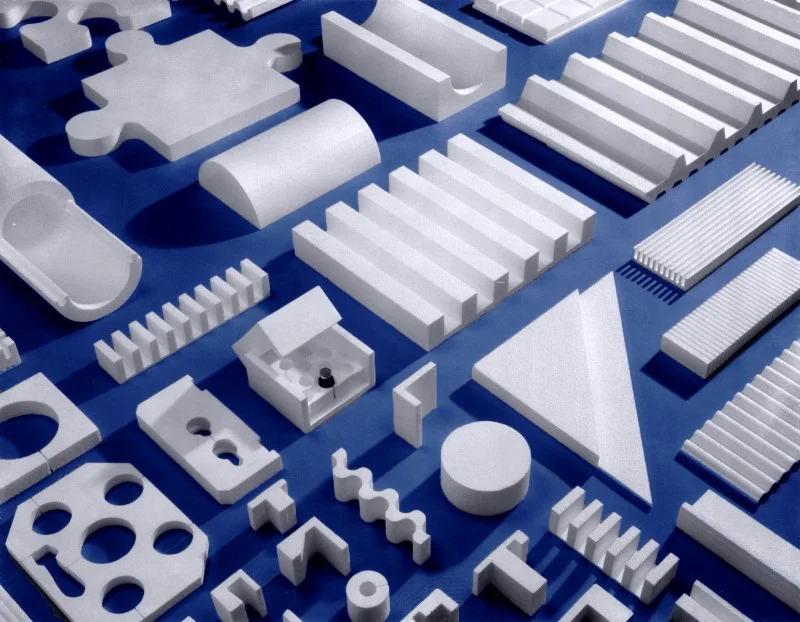

Styrofoam has many names such as blue board, peanuts, etc. The scientific name for this material is expanded polystyrene, which is abbreviated to EPS (expanded polystyrene). The official name is Airpot to emphasise the environmentally aware nature of styrofoam. Styrofoam, after all, contains 2% material (polystyrene) and the rest is air: 98%. This means that with a minimum in material, you get the maximum benefits:

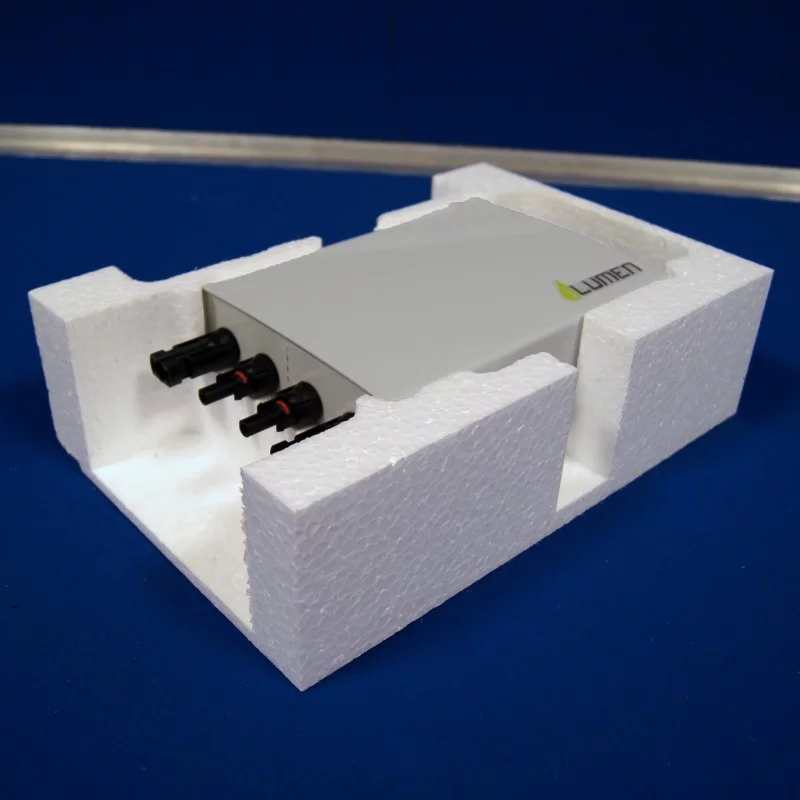

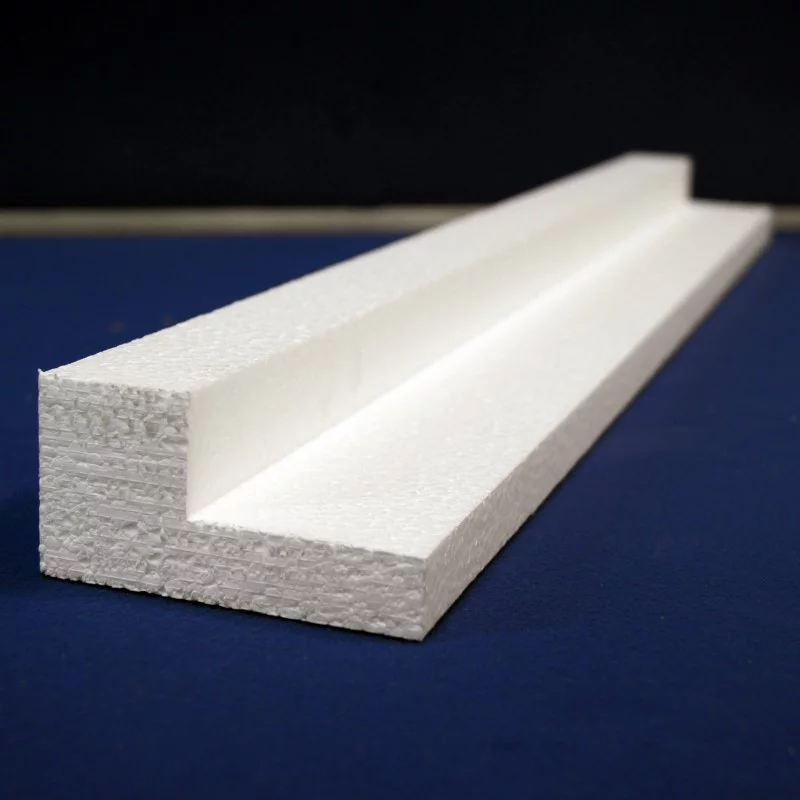

EPS weighs very little and relatively speaking it is very strong. It is fairly elastic but it remains stable. The material has a high shock-absorbing capacity. It is a hard foam with a closed cell structure and therefore upon a heavy impact, EPS will deform so that your product won’t.

EPS insulates perfectly. In addition, EPS is hygienic and is permitted to come into direct contact with food. It also barely absorbs moisture and it can resist most salts, acids and vegetable oils. EPS can only be painted using water-soluble paints (not with polyester or solvent-based paints). Using it is environmentally responsible, it is absolutely free from chlorofluorocarbons (CFCs), it is produced energy efficiently and can be fully recycled.

Expanded polystyrene stands out due to a favourable price/quality ratio that is also self-extinguishing. Both are available in various hardnesses so that the resistance against compressibility can be selected based on the application. EPS is processed in-house starting from blocks. Products are manufactured from these blocks by means of contour cutting, routing, turning and possibly installation. All residual material that is created during production is processed in-house for a second life cycle.

Download the EPC technical sheet

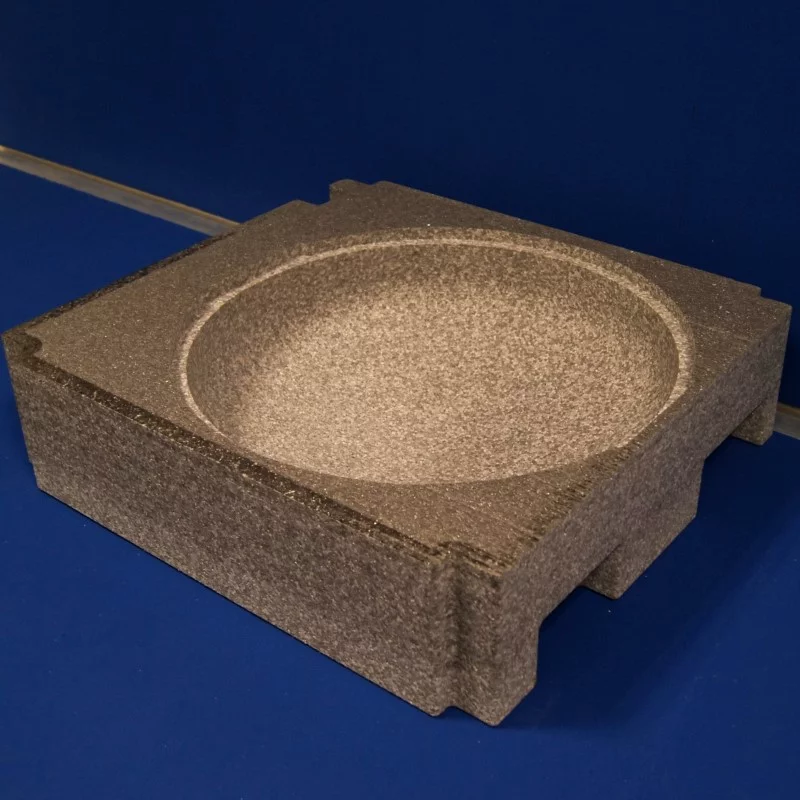

NEOPOR (expanded polystyrene with graphite)

EPS is also available in a grey version that is called Neopor. This is EPS enriched with graphite to improve the insulation value (up to 20%). The lambda value (heat conductivity) varies depending on the density between 0.032 and 0.030 W/mK. The same properties and characteristics as for white EPS also apply. Neopor can also be cut or routed in boards in simple or complex shapes.

Download the Neopor technical sheet

Find your tailor-made solution

Contact us and we will send you a custom made offer within 7 days.